SMD LEDs are a mature technology offering good uniformity, especially after calibration, very good viewing angle, both horizontal and vertical, and ease of servicing, but as demand for smaller pixel pitch increased and SMD LED packages become smaller the technology begins to fail in several areas.

• Variations in LED brightness profile combined with increased pixel density increases wide angle graininess, which cannot be improved by calibration.

• Smaller LED packages result in smaller and weaker solder pad joints.

• LEDs are prone to handling damage during manufacturing resulting in increased repairs which then create long term reliability issues.

• LED Panels require more careful handling to prevent damage during shipping and in operation.

• Weaker LEDs mean more repairs during the warranty period.

• To compensate for weaker LEDs customers are paying for higher quantities of additional spare modules.

• Indoor SMD LEDs are prone to humidity damage.

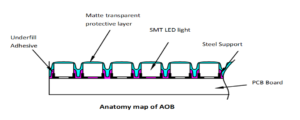

The patented AOB technology solves these issues with an insulating, bonding layer which attaches the LED package to the PCB substrate, and an additional matt transparent nano coating, which adds further protection while improving wide angle uniformity.

• AOB does not impact the positive features of SMD LEDs.

• AOB improves wide angle viewing uniformity.

• AOB improves SMD to PCB sheer strength from 1kg to 6kg.

• AOB improved moisture protection.

• AOB lowers PPM failures from 10ppm to under 5ppm.

• AOB improves scratch resistance.

We offer a wide range of small pitch indoor products using AOB technology. Please contact us to discuss further.