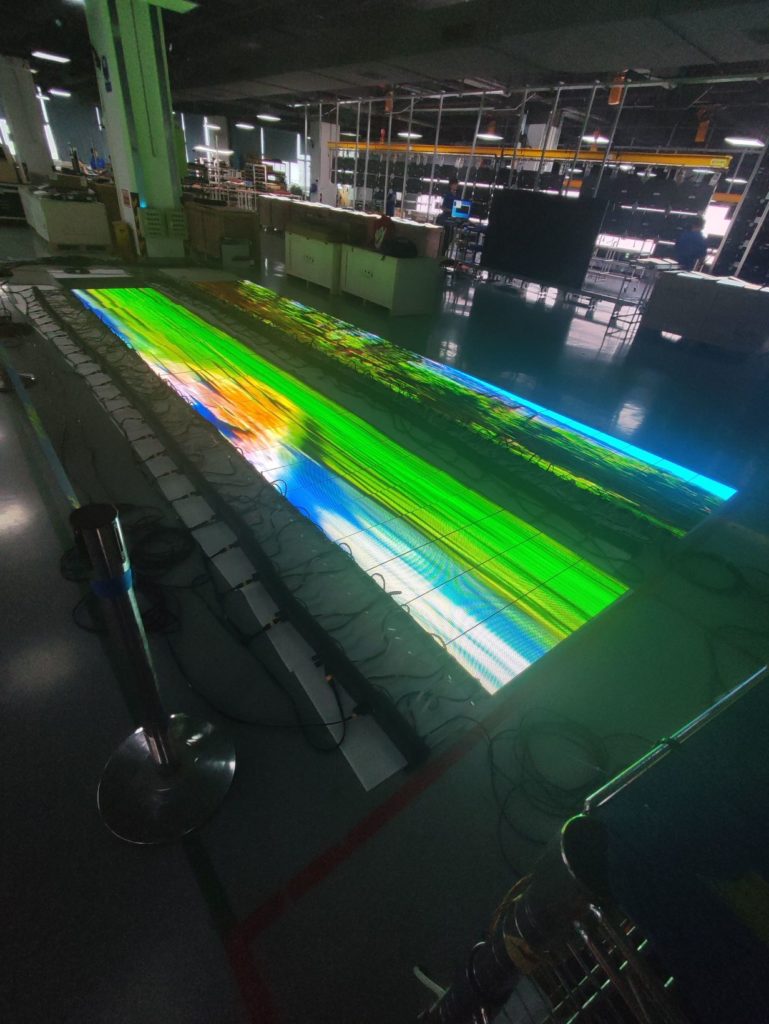

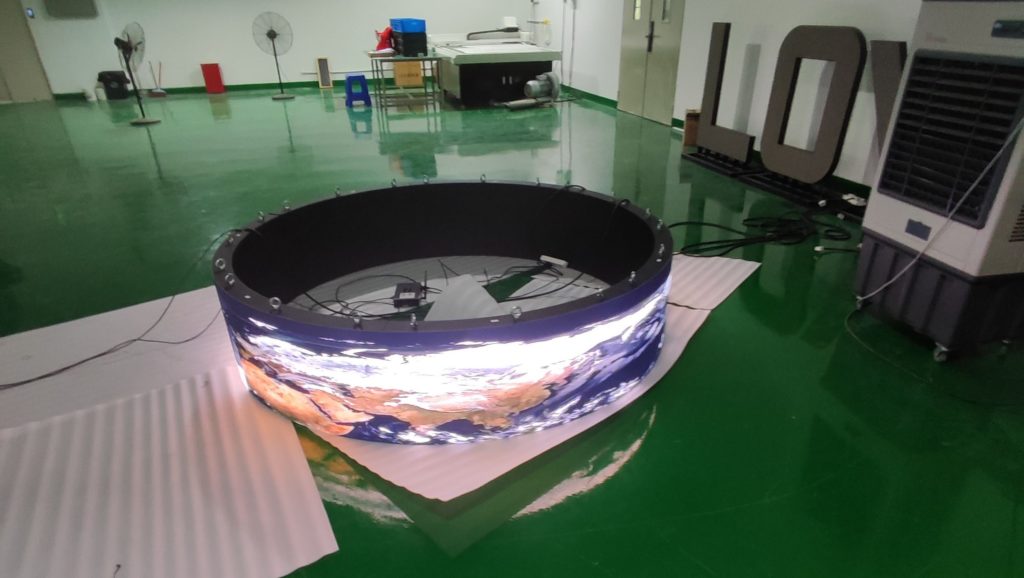

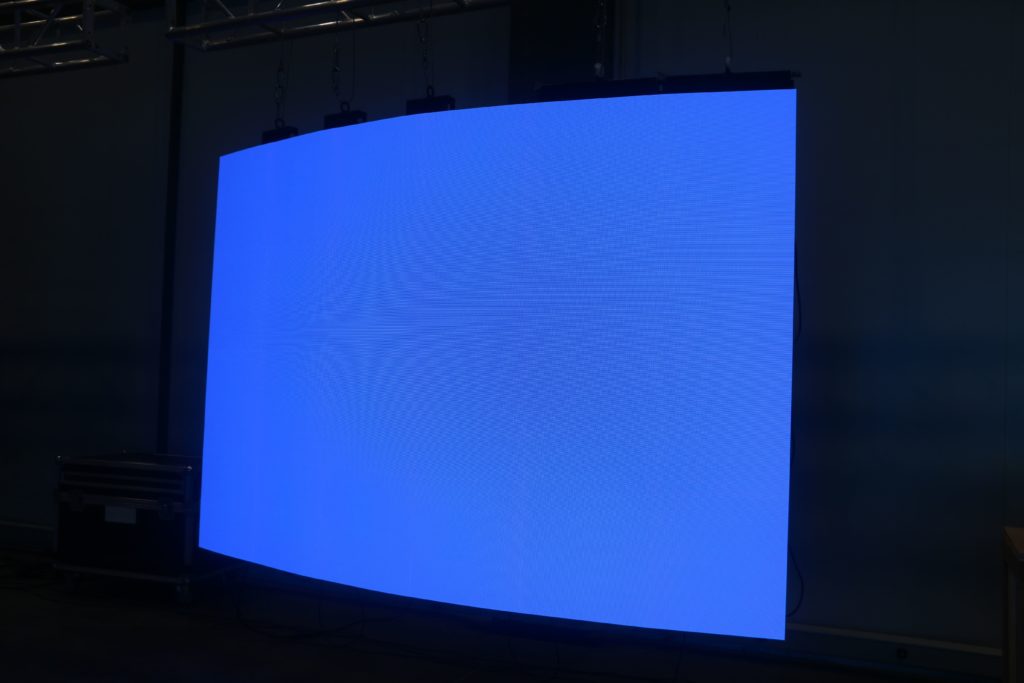

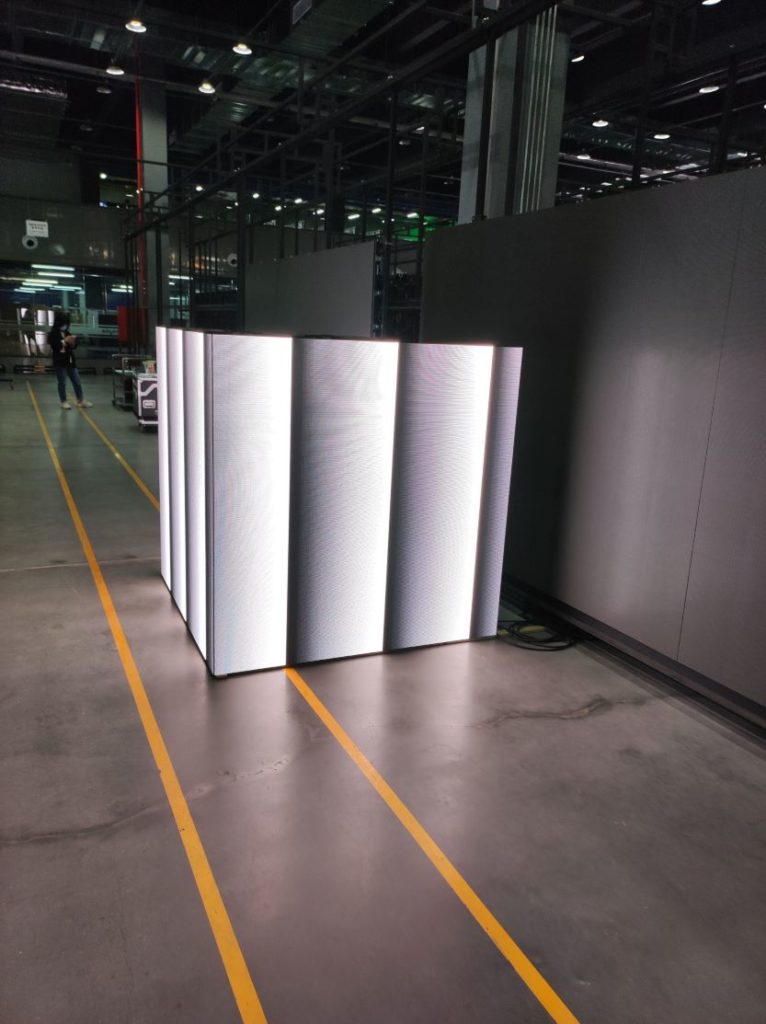

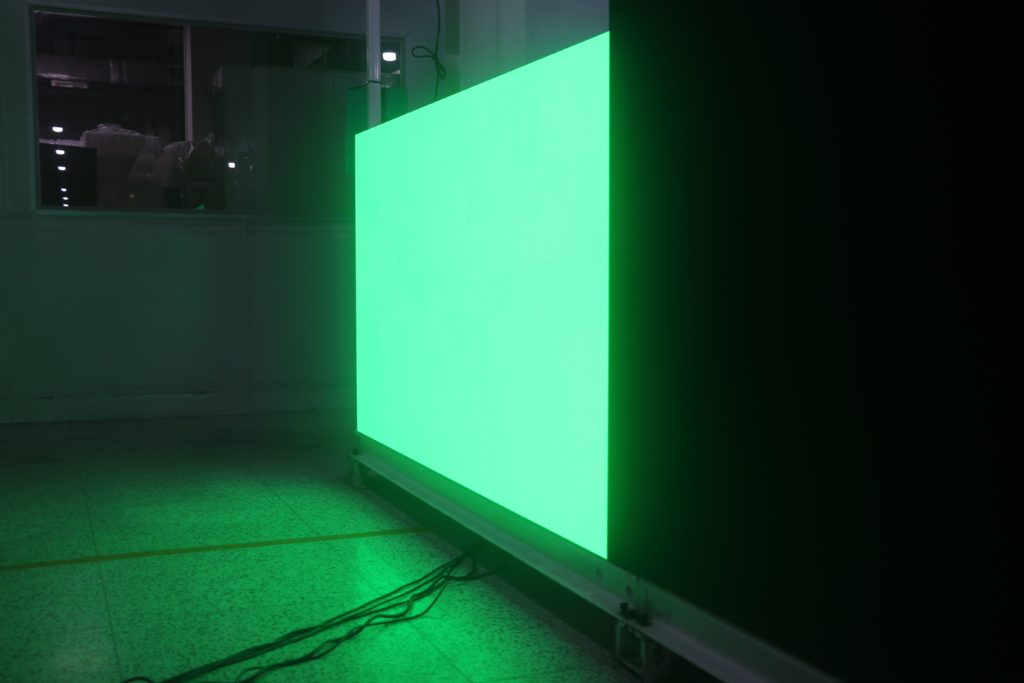

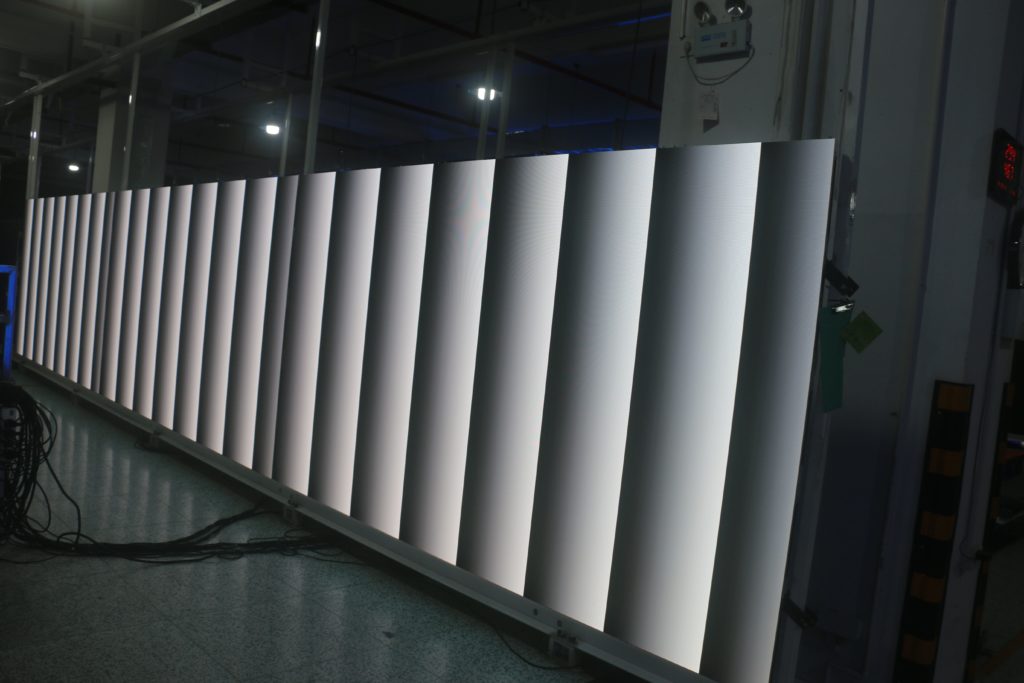

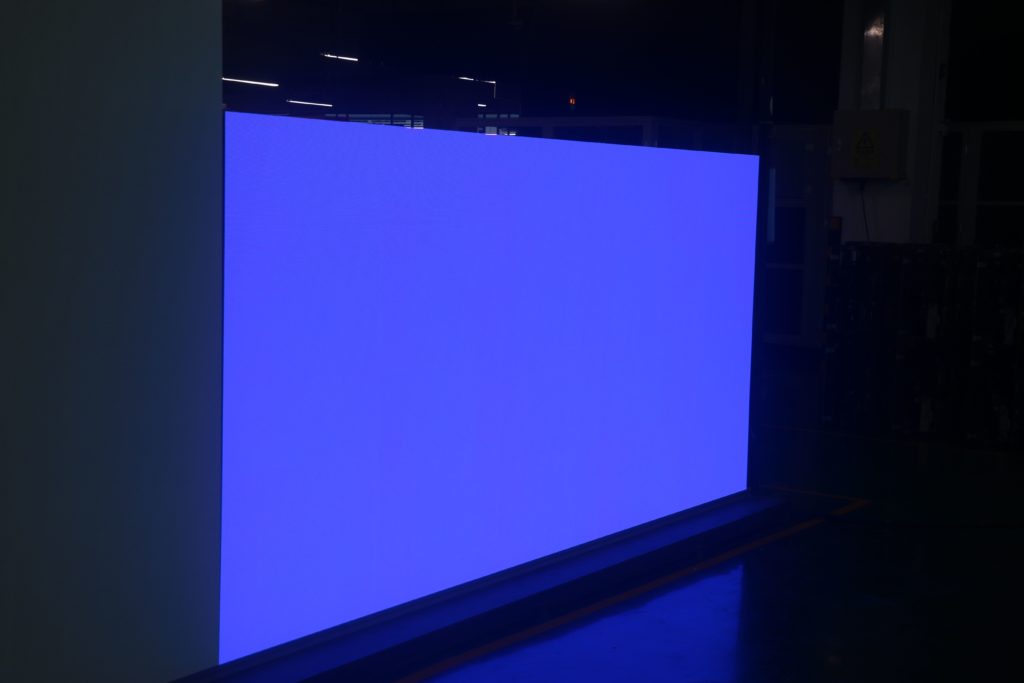

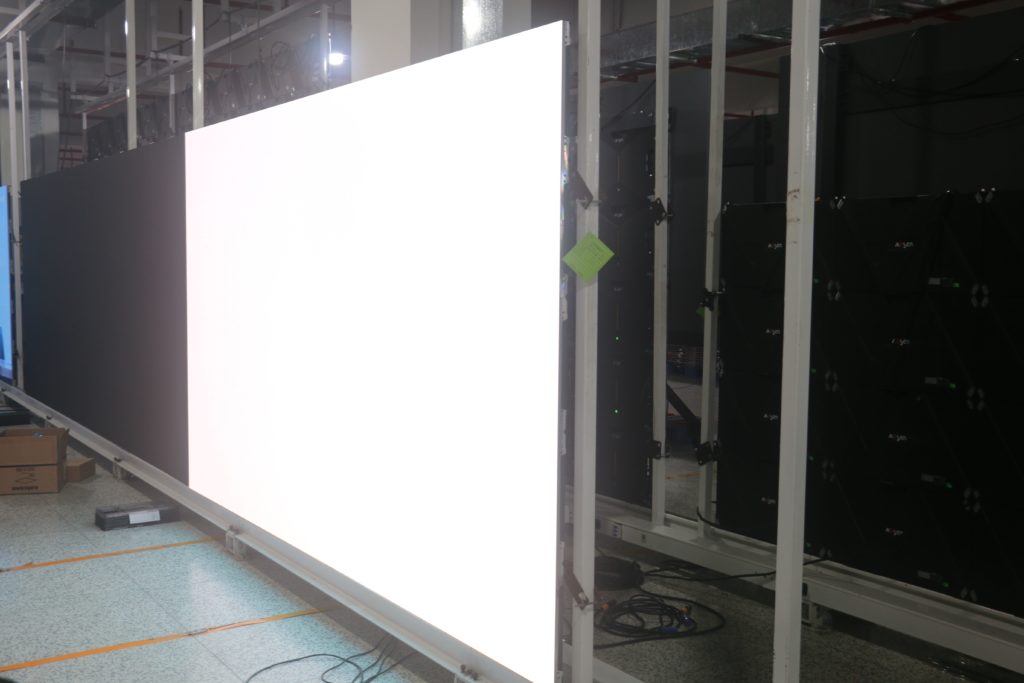

During the second and third week of July 2024 we conducted FATs on over 350sqm of mostly events ready indoor product at a pitch range of 2.5-2.6. We also inspected P1.2 fixed install COB product, including events ready outdoor product at a pitch of 3.9.

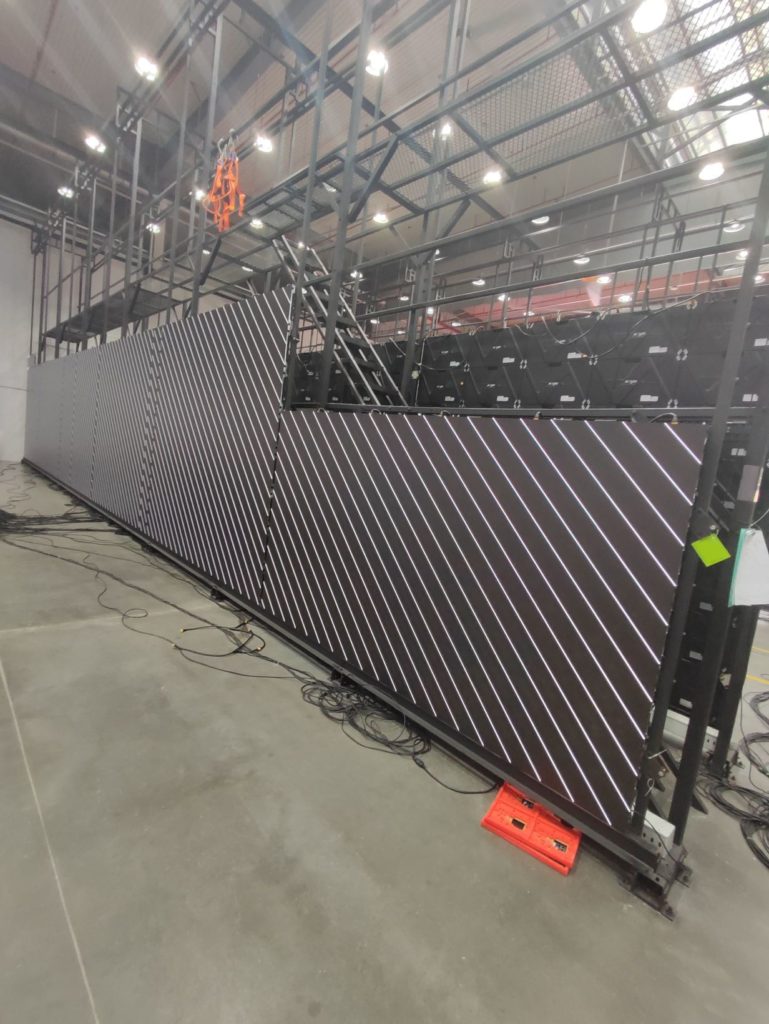

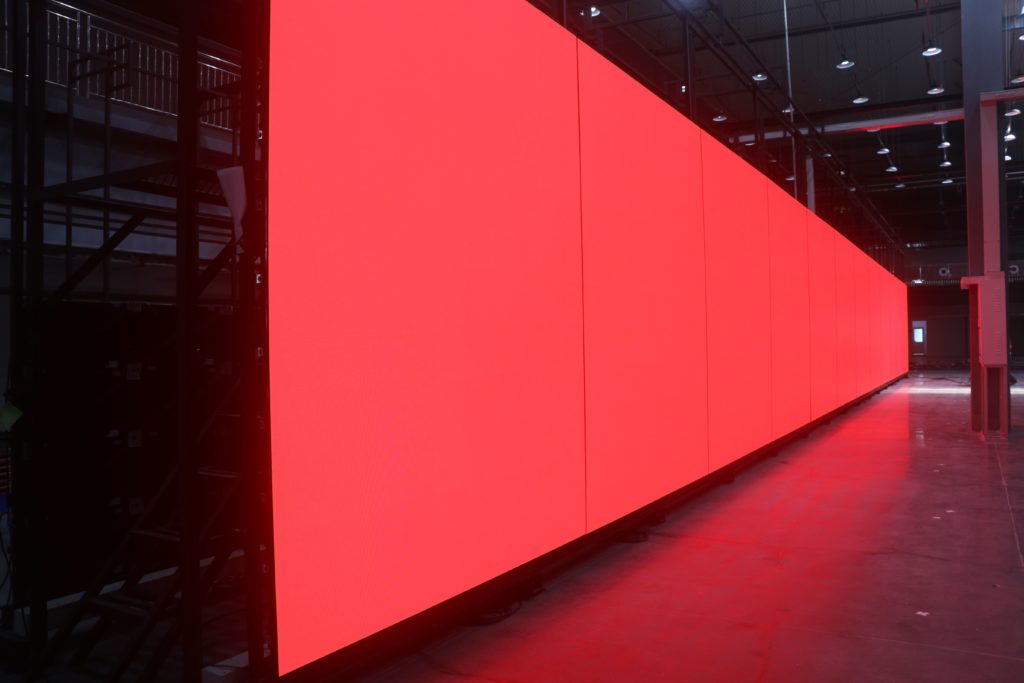

The following is an image of events ready outdoor product P3.9 125sqm.

To discuss your inspection or LED supply needs please enter your name/email in the contact us field at the top of this page.