2022 has seen almost a 30% increase in LED display screen FATs compared to 2019, the last Covid free year, but 2022 has also seen many more challenges than in previous years both in terms of manufacturing failing to meet committed schedules and also the volume of issues identified during the inspection.

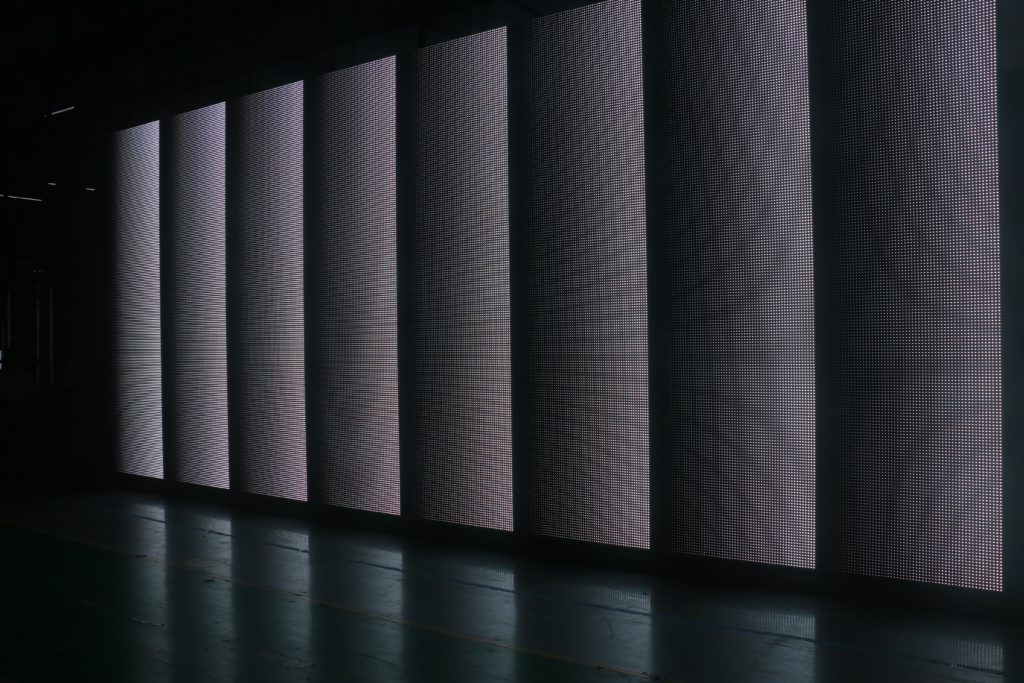

A factory acceptance test is the opportunity for the manufacturer to demonstrate that the product meets specification and performance criteria. It takes place after the factory has conducted its final QC stage and should therefore be ready to pack, yet only 7% of LED display screens passed FAT without corrective action in 2022.

For the most part we are conducting FATs at well known manufacturers at the top end of the manufacturing scale but if you are still wondering why you need an FAT for your new LED display screen purchase here are 6 reasons.

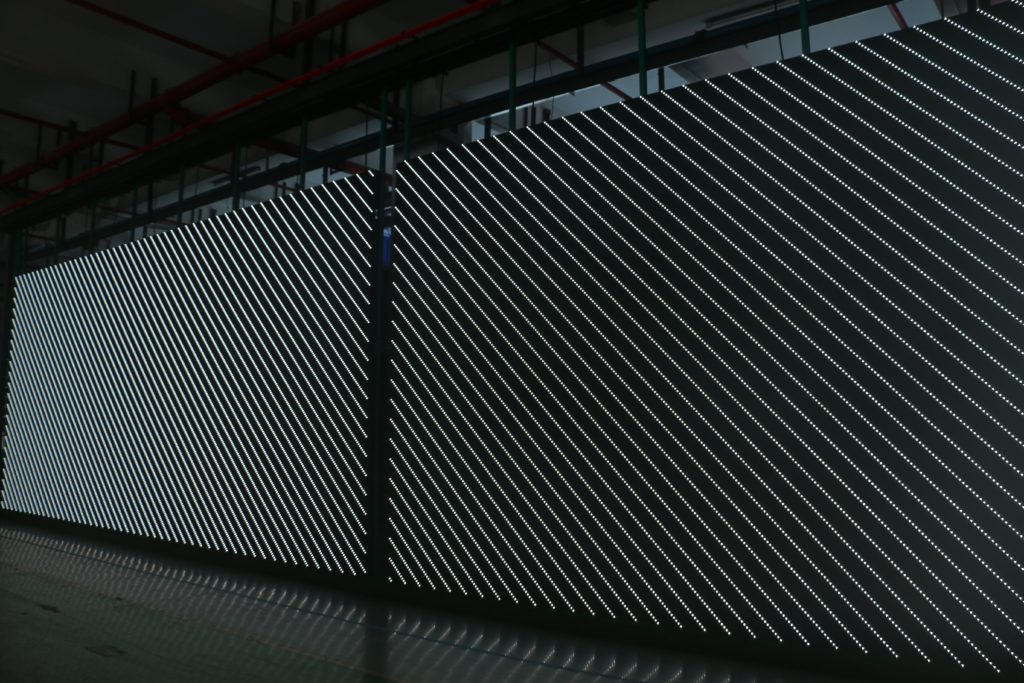

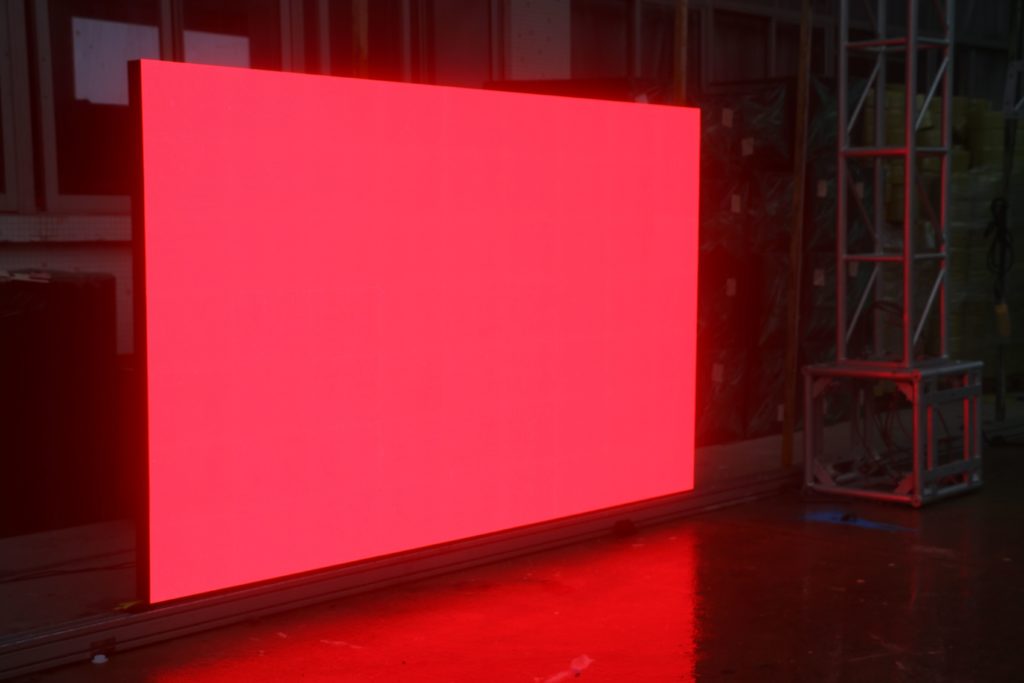

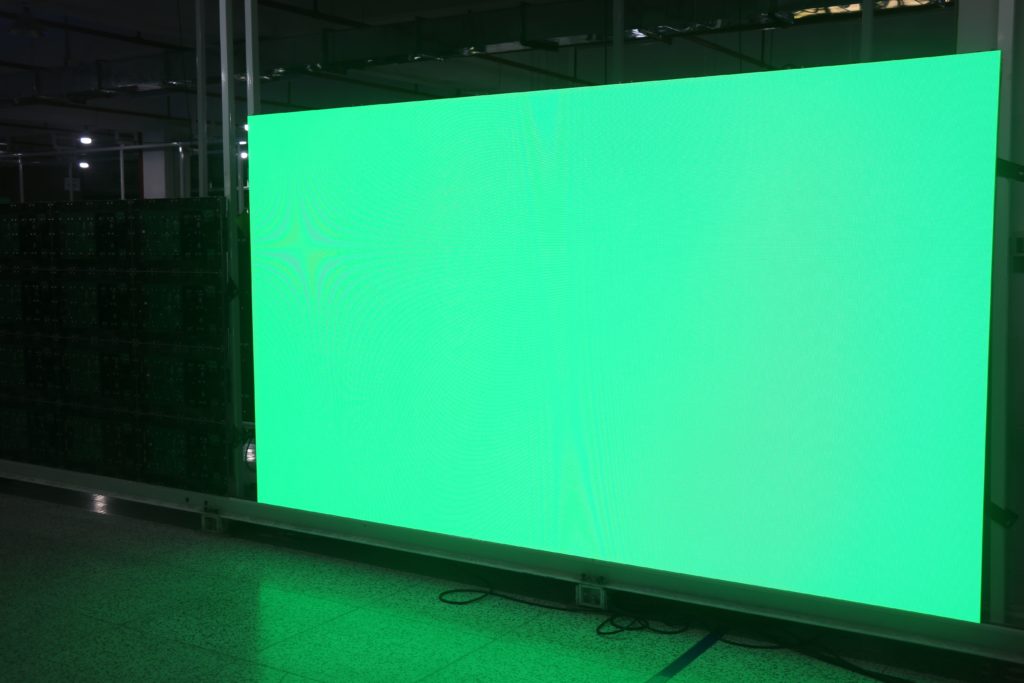

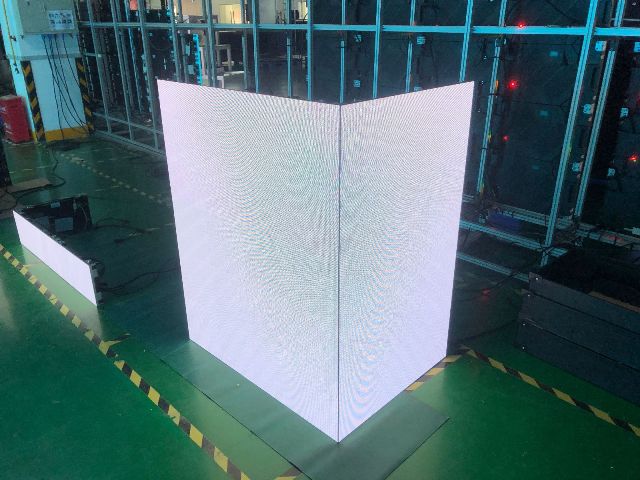

- 55% of screens had electronic failures during FAT including dead LEDs, IC issues, dull or bright LEDs, soldering issues etc.

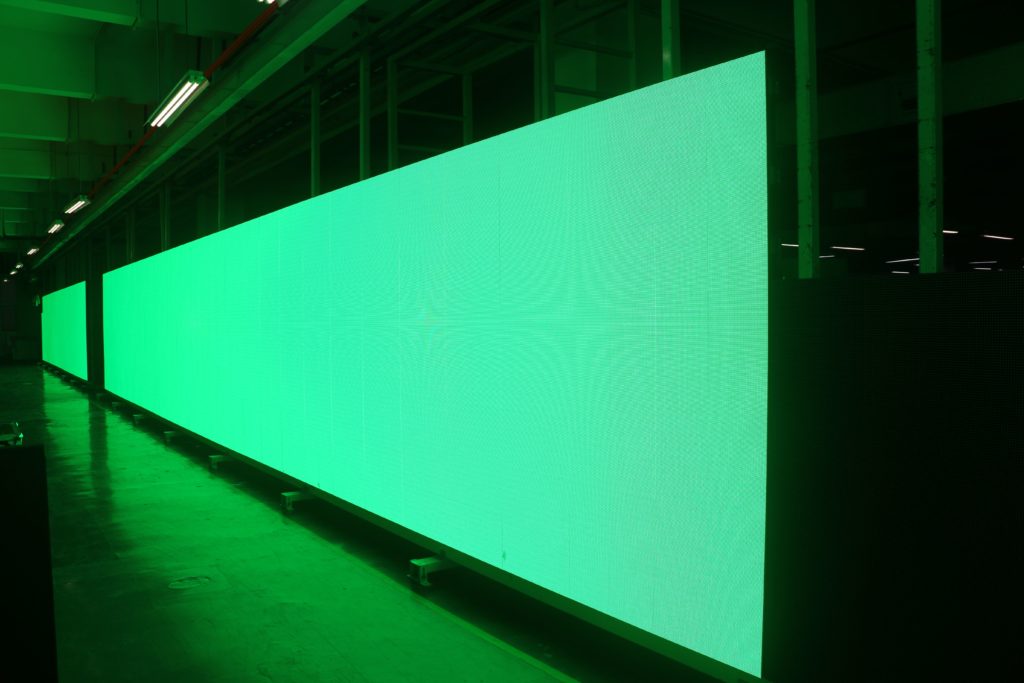

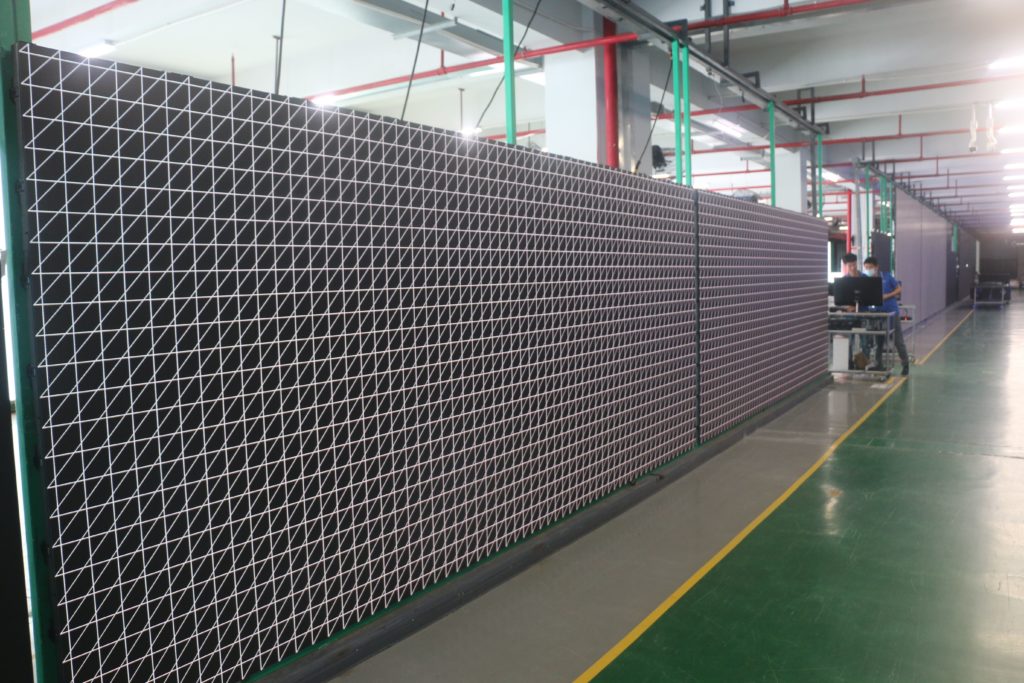

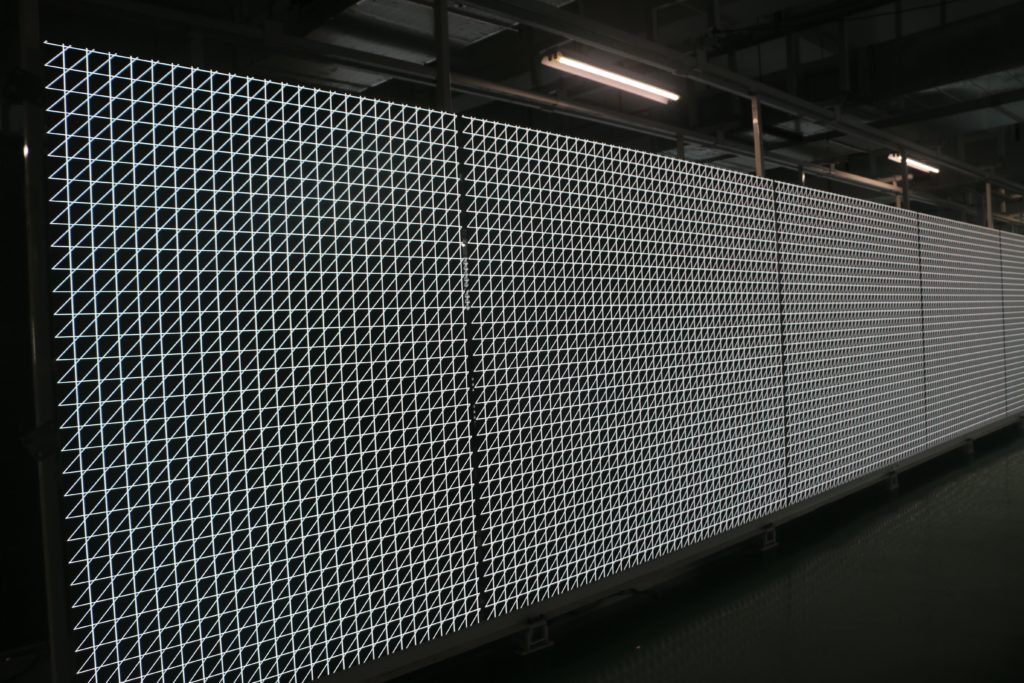

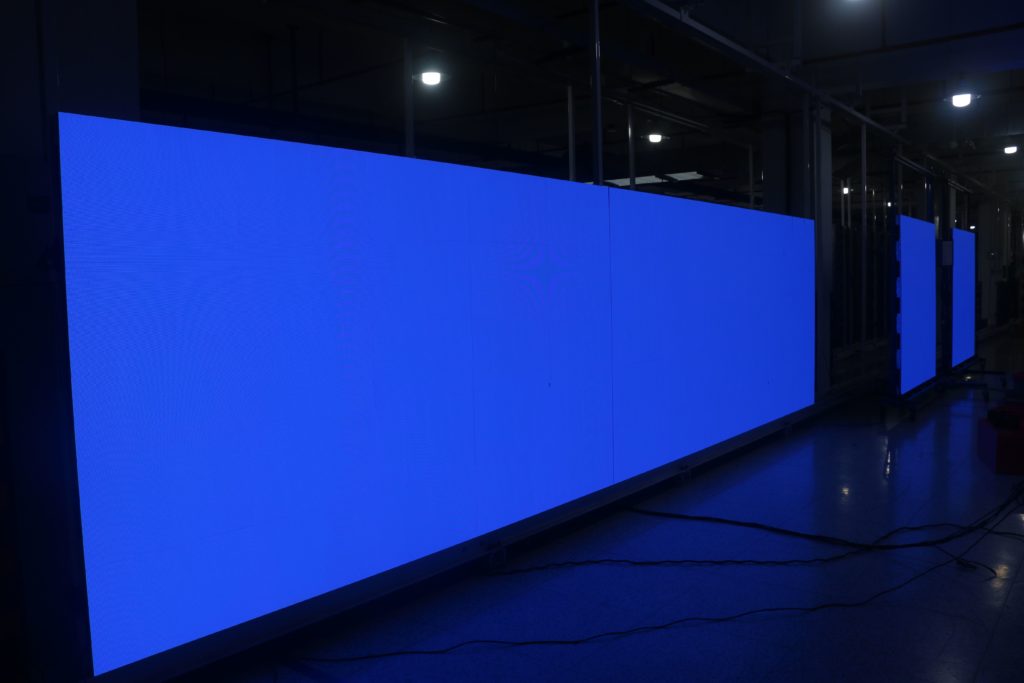

- 49% of screens had mechanical issues such as black patchiness, module gaps or steps, flatness issues, loose, missing or misplaced masks, latch issues etc.

- 33% of screens were not ready for the FAT, including not all panels available, aging not complete, calibration not done, spare parts or flight cases not available, final factory QC not done but the majority or 20% of FATs were postponed often with little or no notice.

- 26% of screens had scratches or paint issues either due to inadequate supplier control, missed at IQC or handling damage during manufacture.

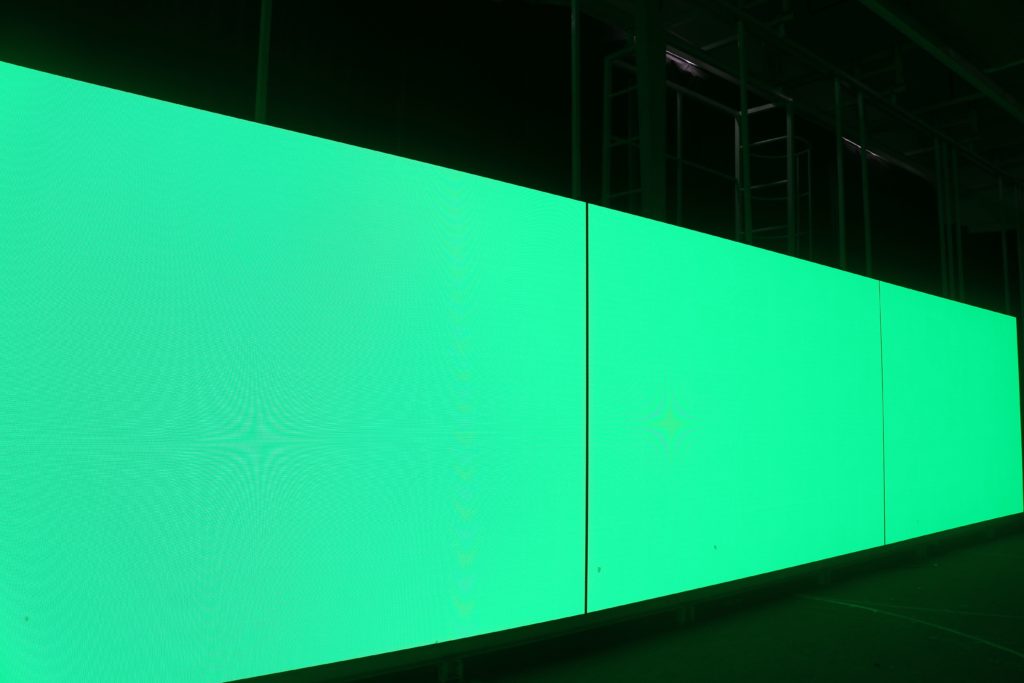

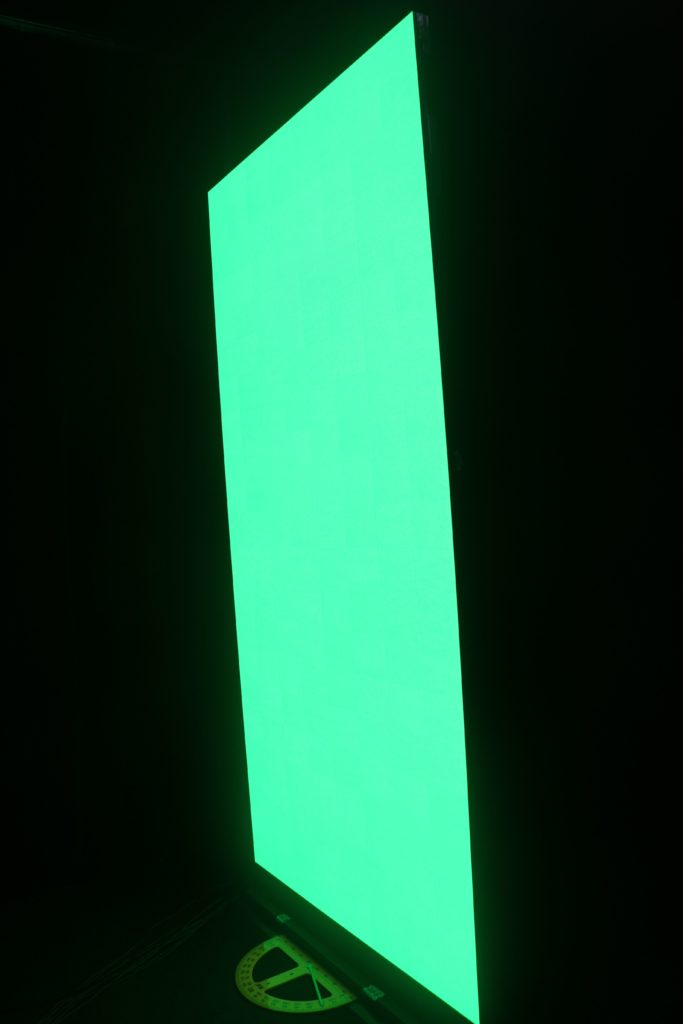

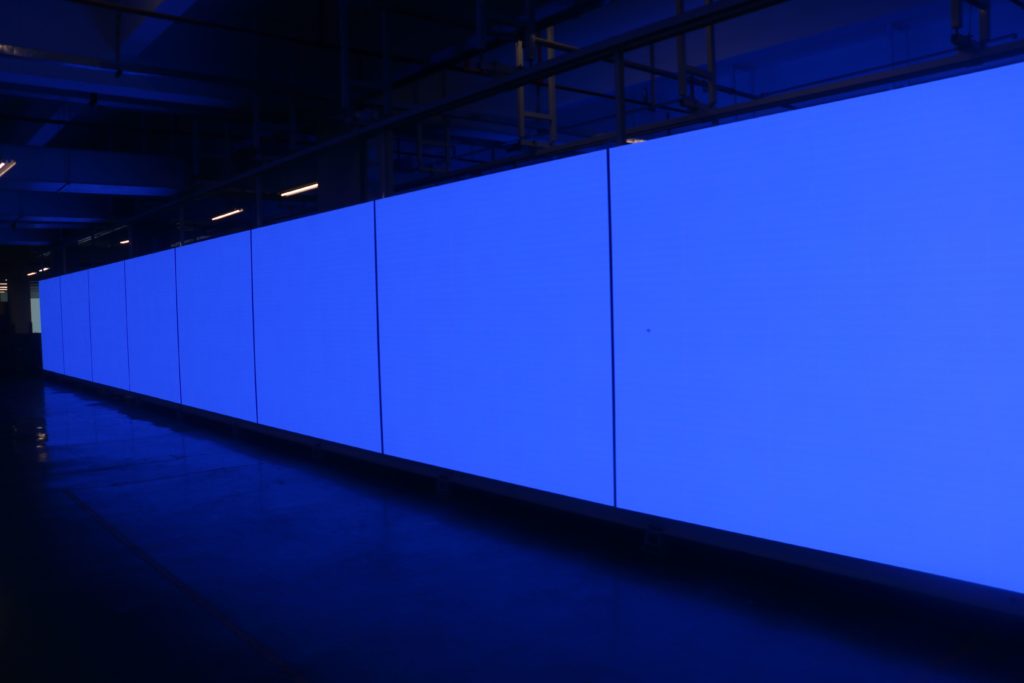

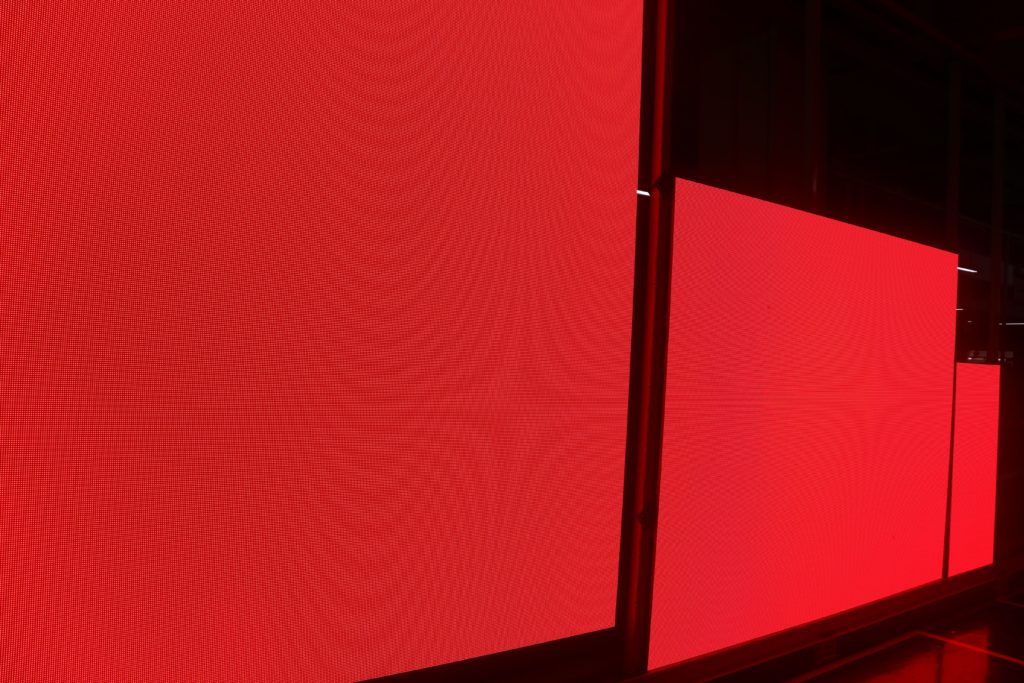

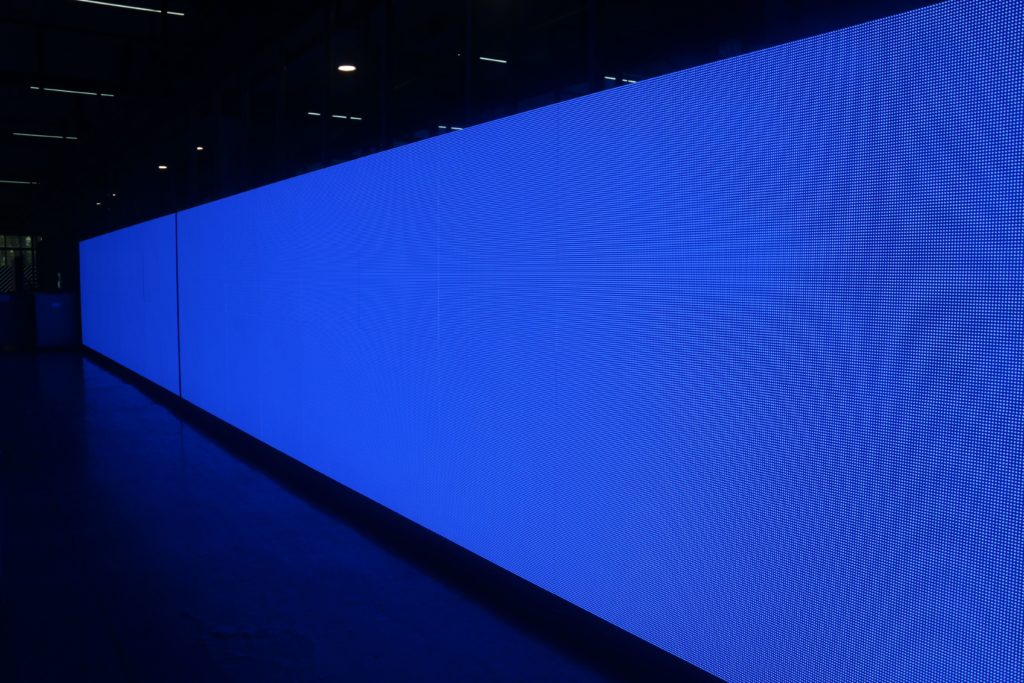

- 20% of screens were patchy on white, red, green or blue.

- 3% of screens had visible thermal effects.

The majority of issues can be resolved through factory rework but our detailed FAT and clear reporting offers the client the support needed to make sure that whenever possible these issues are resolved before shipment and not after the goods arrive in your warehouse. It is always so much more difficult and costly to get corrective action after delivery.

Our FATs are conducted by industry veterans with considerable experience in LED display screen manufacture, we provide a detailed report and support the report with images and videos of all stages and everything found during the FAT so that the client can analyze the findings and reach a qualified decision on any concerns raised. Being locally based in Shenzhen & Dongguan, and operating mainly in the Shenzhen, Dongguan, Huizhou areas means we can handle late schedule changes far easier and at lower cost than overseas visitors. We can also conduct FATs in other regions of China more cost effectively than overseas visitors.

To discuss your next screen order requirement please leave your name and email in our contact box located in the page sidebar. Thank you.